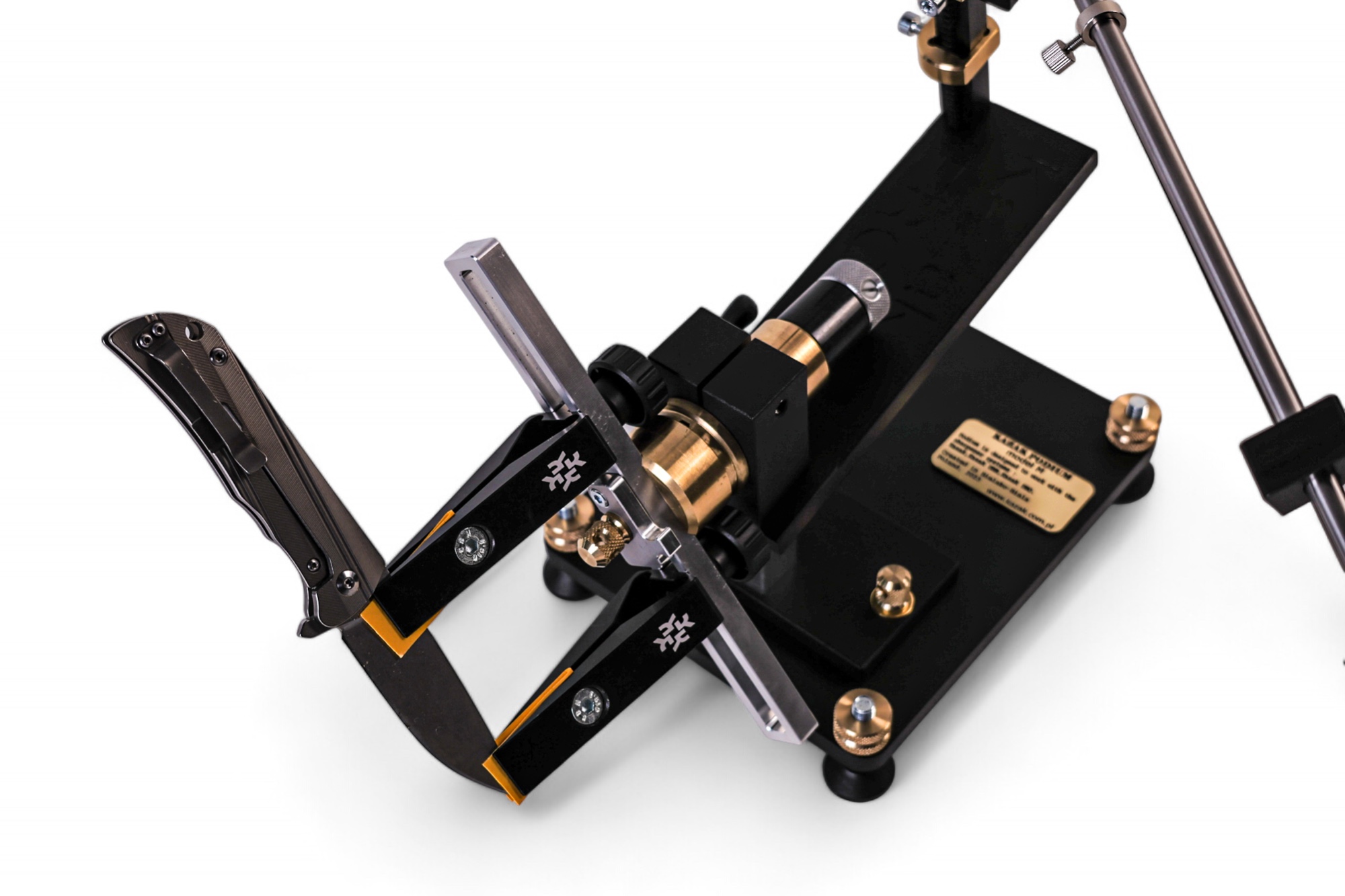

The device is designed for sharpening kitchen, hunting, folding knives of various shapes and sizes. Thanks to the precise and stable fixation of the knife in the clips of the device, as well as the ability to turn the knife without removing it from the clips, sharpening is fast, easy and does not require special skills of the operator.

The device “Kazak PRO” has a quick adjustment unit (UBR V.2) of the sharpening angle, which is a toothed rail along which, when the handwheel rotates, a carriage with a hinge moves. This solution allows you to change the sharpening angle quickly and accurately, literally in one movement.

A little bit about the new node of UBR V.2 which is included in the kit of the KAZAK PRO BLACK version sharpener :

Main parameters :

– upper hole with M8 thread in the rail, used for mounting the “lighting system”.

– the rail is made with milling of two roads

– gear with two roller necks

– side screws are used to control the braking force

In this way, the gear part transmits torque, and the smooth part gives smooth running and pressing of the carriage to the rail.

The sliding unit has an analog goniometer for adjusting the sharpening angle.

The durable sleeve and carriage are made of polyacetal plastic.

Thanks to the use of modern artificial plastics, the node works smoothly and easily.

The entire UBR unit requires absolutely no additional lubrication.

Technical specifications :

Materials of manufacture – steel, aluminum, brass, durable plastic polyacetal.

The price of dividing the scale of the goniometer is 1 degree.

The inner diameter of the plastic sleeve is 8 mm

The height of the rail (vertical rack) – 230 mm

Carriage stroke 191 mm

The connecting thread of the rail (vertical rack) is M8.

The weight of the whole node is 710 grams.

The original is the node for adjusting the angular position of the entire device in the vertical plane, which makes it possible to adjust the position of the device in accordance with the individual requirements of the operator.

*For international orders, consult with your local customs regarding import tax and duties. The recipient is responsible for this payment.

The blade clamps of the original design are made of alloy 7075, heat-treated .

The horizontal guide rod with a diameter of 8 mm is made of alloy stainless steel, has a hardness of 58-60 HRC, surface roughness of 0.4 Ra.

In our sharpening systems, for the first time, the tilt of the sharpening system relative to the operator was implemented for the convenience of controlling the sharpening of the knife.

The first parking hook built into the sharpener has been implemented.

The first removable frame.

The first mass production of fully milled knife clips.

Design features of the sharpener:

– reinforced rotary unit

– quick-release frame of the rotary assembly. It allows for a thorough inspection of the quality of the sharpened knife during the sharpening process.

– ability to lock the rotary unit.

The basic equipment includes:

– platform for electronic goniometer

– stone thickness compensator + angle adjustment unit lock

– 4 mm hex screwdriver

-clamp

– branded box with filler and handle

– node UBR V.2 new generation

-podium ” Kazak-M”

No products in the cart.

No products in the cart.